Today, we mainly introduce all aspects of chillers (especially water-cooled screw chillers), so that you can better understand the chillers, so that the function of chillers (especially water-cooled screw chillers) can be effectively utilized!

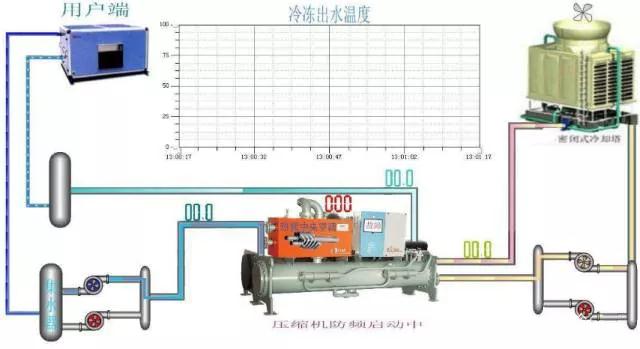

The chiller refrigeration system consists of four basic parts, namely a compressor, a condenser, a throttle, and an evaporator. The four large pieces are connected by a copper tube into a closed system in a certain order, and the system is filled with a certain amount of refrigerant.

The compressor sucks in the low-temperature and low-pressure Freon gas from the evaporator, compresses it into a high-temperature and high-pressure Freon gas, and then flows through a thermal expansion valve (capillary), throttling into a low-temperature and low-pressure Freon-liquid two-phase object, and then low-temperature and low-pressure. The freon liquid absorbs heat from the indoor air in the evaporator, so that compression----condensation---throttle----evaporation repeats the cycle.

First, the chiller

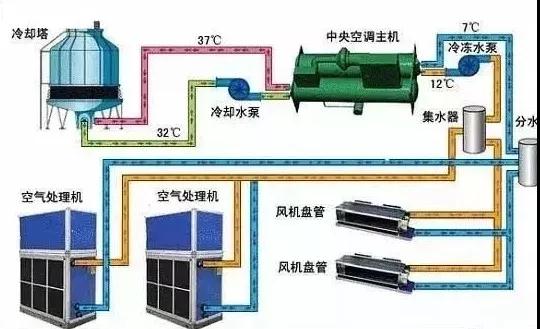

This is the "refrigeration source" of the central air conditioner, the "heart", the circulating water to each room is "internal exchange" by the chiller, and the cooling is "cooling water".

Second, the external heat exchange system

Chilled water circulation system: consists of a refrigerating pump and a chilled water pipe. The chilled water flowing out of the chiller is pressurized by a refrigerating pump and sent to the chilled water pipe, and heat exchange is performed in each room to remove the heat in the room, which is a temperature drop in the room.

Cooling water circulation system: consists of a cooling pump and a cooling water pipe and a cooling tower. The chiller performs heat exchange, and when the water temperature is cooled, a large amount of heat is released. This heat is absorbed by the cooling water and the temperature of the cooling water rises. The cooling pump presses the warm cooling water into the cooling tower to exchange heat with the atmosphere in the cooling tower, and then cools the cooling water and returns it to the chiller.

Third, the cooling fan

Indoor fan: Installed in the room where cooling is required to blow air cooled by chilled water into the room to accelerate heat exchange in the room.

Cooling tower fan: used to reduce the water temperature of the cooling tower and accelerate the heat brought back by the “return water” to the atmosphere.

Fourth, the chiller start and run

▌ Check the oil level and oil temperature of each compressor: the oil level is 1/3~2/3; the oil temperature is 50°C~60°C, and the hand heater should be hot.

▌ Check the main power supply voltage and current: the power supply voltage is in the range of 340V ~ 440V; the three-phase voltage unbalance value <2% (> 2% absolutely can not be turned on); the three-phase current unbalance value <10%.

▌ Start the chilled water pump and the cooling water pump: After the circulation of the two water systems is established, adjust the opening of the evaporator and condenser inlet and outlet valves.

▌ Check the chilled water supply temperature: Whether the set value is suitable or not, it can be changed.

▌ Check before starting: Check the tightness of the electrical joint (main circuit, control circuit), at least the oil tank should be heated for 24 hours, so that the oil tank temperature can not be lower than 38 degrees.

▌ Check before starting: Check the status of each valve of the unit, water pump, pressure gauge, thermometer, filter, etc.

▌ Check before starting: Check the end of the unit. Check the condition of the cooling tower.

▌ Check before starting: Firstly open the chilled water pump and cooling water pump of the water system to check whether the water system is running normally, ensure that the gas is not entrained, and ensure that the water pressure of the water system falls within the required range.

V. Monitoring and adjustment of chiller operation

For chillers, the following should be mainly concerned during operation:

◆ The temperature and pressure of the chilled water inlet and outlet of the evaporator.

◆ The temperature and pressure of the condenser cooling water inlet and outlet.

◆ The pressure and temperature of the refrigerant in the evaporator.

◆ The pressure and temperature of the refrigerant in the condenser.

◆ Current and voltage of the main motor.

◆ Lubricating oil pressure and temperature.

◆ Is the operation of the shrinking unit stable? Is there any abnormal noise?

◆ There is no leakage of each valve of the unit.

◆ Is the joint with each water pipe tight?

6. Evaporation pressure and evaporation temperature

The pressure and temperature of the refrigerant in the evaporator are the saturation pressure and saturation temperature of the refrigerant, which can be measured by the corresponding instrument or instrument set on the evaporator.

The evaporation pressure and evaporation temperature are closely related to the heat of the chilled water carrying the evaporator. When the air conditioning cold load is large, the return water temperature of the chilled water of the evaporator rises, causing the evaporation temperature to rise and the corresponding evaporation pressure to rise. The cooling capacity of the chiller must be slightly larger than the cooling capacity of the air conditioning design that it is responsible for, otherwise it will not be able to obtain satisfactory air conditioning effect during operation.

According to China's GB/T7666 95 standard (general regulations for the nominal working conditions of refrigeration and air-conditioning equipment), the nominal working conditions of the chiller are 7 °C for the chilled water and 32 °C for the return water. Since increasing the effluent temperature of the chilled water is very favorable to the economic efficiency of the chiller, the chilled water effluent temperature should be increased as much as possible in the case of meeting the requirements of the air conditioner.

Under normal circumstances, the evaporation temperature is often controlled within the range of 3 ° C ~ 5 ° C, 2 ° C ~ 4 ° C lower than the chilled water outlet temperature. Too high evaporation temperature is often difficult to achieve the required air conditioning effect, and too low evaporation temperature not only increases the energy consumption of the chiller, but also easily causes the evaporation pipe to freeze.

The difference between the evaporation temperature and the chilled water outlet temperature increases or decreases with the increase or decrease of the evaporator cooling load. Under the same load condition, the heat transfer coefficient decreases as the temperature difference increases. In addition, the temperature difference is also related to the heat transfer area, and the fouling inside the tube and the accumulation of lubricating oil outside the tube also have a certain influence. In order to reduce the temperature difference and enhance the heat transfer effect, it is necessary to periodically remove the dirt in the evaporator water pipe and actively take measures to lead the lubricating oil back into the fuel tank.

Seven, condensing pressure and condensation temperature

The refrigerant in the condenser is also usually saturated, so its pressure and temperature can be looked up by each other through the thermodynamic properties of the respective refrigerant.

The condensing temperature of the water-cooled unit is generally higher than the cooling water outlet temperature of 2 ° C ~ 4 ° C, if the temperature is too high, it should be checked whether the copper tube inside the condenser is fouled and needs to be cleaned.

The level of condensation temperature, in the case of constant evaporation temperature, is decisive for the power consumption of the chiller. The condensing temperature increases and the power consumption increases. Conversely, the condensing temperature is lowered and the power consumption is reduced. When the air is present in the condenser, the temperature difference between the condensation temperature and the cooling water outlet increases, and the temperature difference between the inlet and outlet of the cooling water decreases, and the heat transfer effect of the condenser is not good, and the condenser casing has a hot feeling.

The fouling of the water side of the condenser tube and the effect of the sludge on heat transfer also play a considerable role. Therefore, when the chiller is running, care should be taken to ensure that the cooling water temperature, water quantity, water quality and other indicators are within the acceptable range.

Eight, the pressure and temperature of chilled water

The chiller for air conditioning is generally operated under the condition that the chilled water return water temperature specified by the nominal working condition is 12 ° C, the water supply temperature is 7 ° C, and the temperature difference is 5 ° C.

It can be known from Q=W×Δt that the chilled water flow rate through the evaporator is inversely proportional to the difference between the supply and return water temperatures, that is, the larger the chilled water flow rate, the smaller the temperature difference; conversely, the smaller the flow rate, the larger the temperature difference.

The principle of valve opening adjustment:

1. The evaporator effluent has sufficient pressure to overcome the resistance in the closed circuit of the chilled water.

2. The chiller operates under the burden of design load, and the temperature difference between the inlet and outlet of the evaporator is 5 °C.

Although the chilled water system is closed, the scale and corrosion in the evaporator water pipe will not be as serious as the condenser. However, from the inspection and maintenance requirements of the equipment, the evaporator pipe and other pipes of the chilled water system should be used every three years. Clean once.

Nine, cooling water pressure and temperature

The chiller operates under nominal conditions with a condenser inlet temperature of 32 ° C, an outlet water temperature of 37 ° C and a temperature difference of 5 ° C.

The principle of adjusting the opening degree of the cooling water pump outlet valve and the inlet and outlet pipe opening degree of the condenser:

1. The effluent of the condenser should have sufficient pressure to overcome the resistance in the cooling water line;

2. When the chiller is operating under the design load, the temperature difference of the cooling water entering and leaving the condenser is 5 °C. It should also be noted that the excessive opening of large cooling water valves, increasing the amount of cooling water to reduce the condensing pressure, and trying to reduce energy consumption can only be counterproductive and counterproductive.

Measures to reduce condensation temperature:

Reducing the inlet temperature of the condenser is to increase the amount of cooling water. However, excessively increasing the flow rate of cooling water often causes the power consumption of the cooling water pump to rise sharply, and the ideal result is not obtained.

Ten, the suction temperature of the compressor

The suction temperature refers to the temperature of the refrigerant gas in the suction chamber of the compressor. The temperature of the intake air not only affects the temperature of the exhaust gas, but also has an important influence on the volumetric refrigeration capacity of the compressor. When the suction temperature of the compressor is high, the exhaust gas temperature is also high, and the specific volume of the refrigerant when it is sucked is large, and at this time, the unit volume of the compressor is small. Conversely, when the compressor intake temperature is low, the unit volume cooling capacity is large. However, if the compressor suction temperature is too low, the refrigerant liquid may be sucked into the compressor, and the compressor should be prevented from "liquid attack".

In order to ensure the normal operation of the compressor, the suction temperature needs to be higher than the evaporation temperature, that is, it should have a certain degree of superheat. For a piston chiller, the suction superheat is generally 5 ° C ~ 10 ° C, if a dry evaporator is used, the superheat degree can be adjusted by adjusting the adjusting screw of the thermal expansion valve. In addition, it should be noted that the length of the compressor suction pipe and the performance of the wrapped insulation material will have a certain impact on the degree of superheat.

XI, the exhaust temperature of the compressor

The compressor discharge temperature is much higher than the condensing temperature. The direct influence of the exhaust gas temperature is the suction temperature of the compressor. The two are proportional. In addition, the exhaust gas temperature is also related to the type of the refrigerant and the compression ratio. In the air conditioning condition, since the compression ratio is not large, the exhaust gas temperature is not high. When the suction and exhaust valves of the piston compressor are not tight or broken and cause leakage (internal leakage), the exhaust temperature will rise significantly.

12. Oil pressure difference, oil temperature and oil level

The lubricating oil system is an indispensable part of the normal operation of the chiller. It provides lubrication and cooling conditions for the moving parts of the unit. Centrifugal, screw and partial piston chillers also need to use lubricating oil to control the energy regulating device or pumping recovery. Device.

Thirteen, the main motor running current and voltage

The rated power supply voltage required by the main motor is 380V, three-phase, 50Hz, and the average phase voltage instability rate of the power supply is less than 2%.

▲ Shangyi quality chiller

In actual operation, the operating current of the main motor increases or decreases with the amount of cooling in the energy regulation when the chilled water and cooling water inlet and outlet temperatures of the chiller are constant. The number of compressors that the chiller is put into operation will affect the magnitude of the operating current. However, when the temperature of the chilled water or the cooling water enters and exits the water, it is difficult to make a correct judgment. The unit's open ammeter reading can reflect the difference between the above two conditions.

14. Closure of the chiller

The shutdown sequence of the air-conditioning water-cooled chiller and its water system is the reverse process of its starting operation sequence, namely chiller→chilled water pump→cooling water pump and cooling tower→air treatment device.

It should be noted that the interval between the chiller compressor and the cooling water pump should ensure that the high temperature and high pressure gas refrigerant entering the condenser is completely condensed into liquid, and preferably all enter the liquid reservoir; and the chiller compressor The interval between shutdown and chilled water pump should ensure that all liquid refrigerant in the evaporator is vaporized into superheated gas to prevent accidents of the freezing tube.

Through the above fourteen categories, I believe that everyone has a more vivid understanding of the chiller (including water-cooled screw chillers).

More exciting, please pay attention to the public number