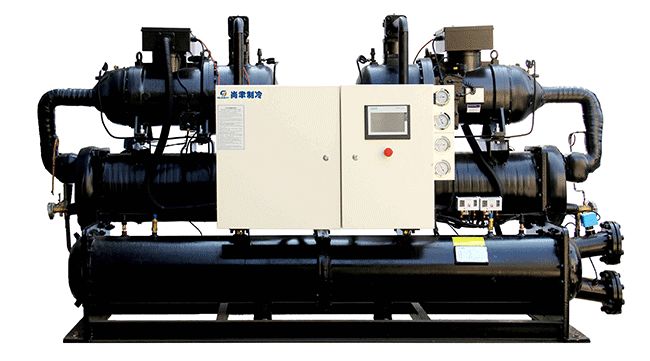

As a fixed asset of an enterprise, an industrial chiller is one of the things that a company must do to maintain it and make it the most useful. It should be noted that the industrial chiller has a fixed maintenance cycle and corresponding maintenance items. Today, Xiaobian shares the maintenance method of the water-cooled screw chiller.

SUNNY-HVAC water-cooled screw series chiller

Daily maintenance and inspection

1) Remove the garbage and debris during installation and repair, and keep the environment of the equipment room and the surrounding area of the unit clean;

2) Remove dust and dirt exposed to the pipeline to detect leaks and repairs in a timely manner;

3) Check whether the heat-insulating materials of the heat exchanger and the pipeline are in good condition. If it is found to be damaged or peeled off, it should be repaired in time;

4) Check the fasteners of the unit for looseness, properly tighten the fasteners, eliminate vibration and prevent leakage;

5) Check whether the line voltage of the unit power supply and the imbalance of each phase voltage are within the specified range;

6) Record the operating data of the unit: unit voltage, current, high and low pressure gauge pressure, freezing inlet and outlet water temperature, cooling water inlet and outlet water temperature, compressor exhaust temperature, etc.;

7) Check if the pressure indicated by the high and low pressure gauge of the unit is normal;

8) Check the drying filter. If frosting is found at this position, the filter is blocked and the filter element needs to be replaced.

9) Check the moisture indication of the sight glass. If yellow is displayed, replace the dry filter core.

▲Note: The monitor can truly reflect the moisture content of the system after at least 4 hours of operation.

Weekly maintenance

1) Review the inspection operation record this week;

2) Apply butter to the valve stem of each valve of the equipment and a few drops of oil on the door hinge and door lock of the control cabinet to prevent the moving parts from rusting and biting.

Regularly check items every month

1) Check if the screws of each device are loose;

2) Check if the pipe joints leak;

3) Check whether the wires are worn, whether the connection is firm, and whether the joints are burnt or not;

▲Warning! ! In order to prevent casualties caused by electric shock or contact with moving parts, the isolating switch of the locking unit is in the disengaged state.

4) Check if the oil level of the compressor is normal;

5) Check whether the freezing and cooling water systems are exposed to air;

6) Check if the refrigerant pressure is normal;

7) The surface of the condenser is cleaned and descaled;

8) Check if the expansion tank and make-up water are normal.

Every three months of maintenance

1) Review the inspection operation record;

2) Check the oil level and refrigerant charge (by high and low pressure and current);

3) Clean all water filters of the freezing and cooling water system;

4) Check the temperature difference between the inlet and outlet sections of the dry filter when the unit is running at full load.

Every six months of maintenance

1) Review the inspection operation record;

2) Analyze the compressor oil in the laboratory to check the water content and acidity of the refrigerant system. When the pH value is lower than 6, the compressor oil must be replaced in time. If the conditions for checking the acidity are not met, the dry filter core of the refrigerant system should be replaced regularly to keep the system dry.

3) Tighten the control box and all the wire connectors in the starter cabinet.

▲Warning! ! In order to prevent casualties caused by electric shock or contact with moving parts, the disconnecting switch of the locking unit is in the disengaged state.

Annual maintenance

The unit is closed once a year and the unit is checked as follows:

1) Check the oil level and refrigerant charge;

2) Change the oil filter element;

▲Note: It is recommended that if it is not necessary, do not replace the compressor oil unless the oil analysis result is contaminated.

3) Detect any refrigerant leakage at all connections;

4) Check if the high voltage switch and low voltage switch trip value are normal;

5) Test the setting of the oil filter differential pressure switch to ensure that the switch is separated when the pressure difference exceeds 0.34 MPa;

6) Check the dirt level of the condenser cooling water pipe. If the dirt is serious, please clean it according to the contents of 5.2.2.

7) Measure the insulation resistance of the compressor motor winding to ground;

8) Contact a qualified maintenance company to conduct a leak test, operation and safety control on the unit, and inspect the electrical components for defects.

Other maintenance

1) Test the evaporator and condenser tube bundles using non-destructive testing of the pipeline every three years;

▲Note: For the use of industrial chillers, it may be better to shorten the cycle of these tube bundle inspections, especially for some important occasions.

2) Generally, the lubricating oil must be inspected or replaced every 5000 to 10,000 hours of operation, and after the first operation, it is recommended to replace the lubricating oil and clean the oil filter and the compressor suction filter for 2000 to 2500 hours. Because the residue of the system assembly will accumulate in the compressor after the official operation, the lubricant should be replaced once in 2500 hours or 3 months, and then replaced according to the cleanliness of the system. If the system is clean, it can be used every 10,000 hours ( Or replace it once a year. If the exhaust temperature of the compressor is maintained at a high temperature for a long period of time, the lubricating oil deteriorates rapidly, and the degree of deterioration of the lubricating oil needs to be checked according to the cycle recommended in the following table;

▲Note: In the case of the compressor motor burning in the previous case, after replacing the compressor, the unit should be operated for 24-48 hours to replace 1-3 times of refrigerating oil, and the lubricating oil condition or timing should be tracked every month (200 hours recommended) Replace the oil until the system is clean, otherwise the compressor may burn out again.

3) According to the application of the unit, contact the company or a suitable maintenance company to conduct a comprehensive inspection at the agreed time.

For more information, please pay attention to SUNNY-HVAC WeChat official account.